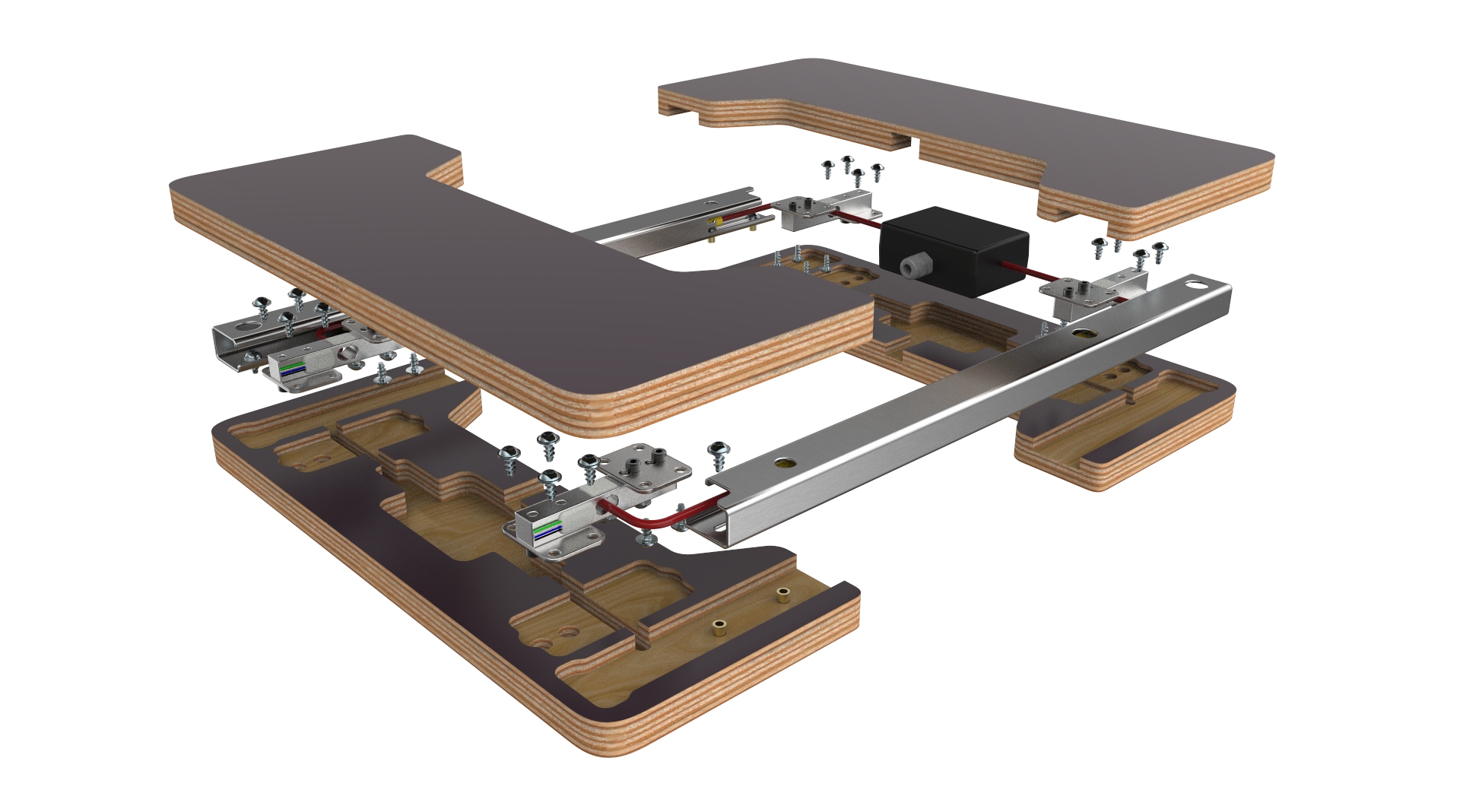

BEEP base version 2

Click on the button below for the details of the BEEP base version 2 (v2).

Specifications BEEP base v2 |

||

| Number produced: | 12 | |

| Sensors: | Total weight of the hive, temperature and noise in the hive, ambient temperature and humidity | |

| Microprocessor: | Atmega328p | |

| Data connection: | LoRa 868MHz (The Things Network or KPN) | |

| Power source: | 2 Lithium AAA-batteries(± 1 year data transmission) | |

| Material/production method: | CNC machined concrete plex and laser cut stainless steel | |

Development status v2

The BEEP base v2 has been tested under several circumstances in February 2019. Measurements have been made with sensors placed both under and inside the hive, and several types of sensors have been tested. Furthermore, ten of the systems have been tested under multiple temperature and humidity circumstances. The following conclusions were derived from the tests:

- Measurement of temperature and humidity (in- and outside of the hive) functions and provides relevant information.

- Wireless transformation of data over the LoRa network functions in the time ranges from once per 15 minutes to once per hour (depending on changes in the measurement values).

- The system is sufficiently energy effiecient to work for one year on two AAA batteries, this includes taking measurement and transmitting information.

- Sound measurement are not yet satisfactory, as too few frequencies are analysed and there is not enough consensus about conclusions you can draw from the recordings.

- The long duration weight measurement are not precise enough in fluctuating outside temperature.

- The CNC milling of the wood is time consuming: it takes about 8 minutes per shelf which adds up to 32 minutes per measurement system.

- The total assembly time of one measurement system is 3 to 4 hours. An affordable measurement system has to be assembled in approx. 15-30 minutes, or be supplied as a DIY kit. So clearly a design step is needed here.

Focus on the hardest measurements: long duration stable weight

Since the measurements of temperature and humidity go well, our current focust is on the most important measurement value: weight. Weightsensors, also called load cells, usually consist of an aluminum bar in which the deformation caused by a load is measured by a change in resistance of a small strain gauge. Load cells are designed to briefly weigh items such as people and goods.

In the case of the hive, however, we want to weigh continuously. Although the sensors are not always switched on (this is not necessary and would take too much power), the load on the hive always presses on the sensors. At the same time, environmental factors such as temperature and direct sunlight influence the measurements. Shifting temperatures in particular affect the reading of the load cells. In v1 we corrected this as much as possible in the software and used this correction in the hardware and software of v2.

Why is reliable weight data so important?

As mentioned, the temperature influences the weight measurements. The extend of the influence varies. For example, when interpreting weight data, one may want to see the difference in weight gain or loss per day. This can vary from half a kilogram to a whole kilogram, depending on the weather conditions. When the actual changes are subtle, e.g. when tracking inventory usage in winter and early spring, these changes easily cause interpretation errors. The current v2 measuring system is accurate to about 200 grams (on a total range of 0-125kg), but we want to go to an accuracy of 50 grams in order to be able to properly visualize small changes.

Other factors also play a role: rain and snowfall, moisture absorption in e.g. wooden hive parts, condensation in the hive. The more variations, the more unreliable and the greater the risk of confusion for the user of the data. This can potentially lead to wrong decisions.